I started my PhD in 1997, by working on the optimization of a linear Delta architecture for Renault Automation (now belonging to COMAU group). My work was to optimize the kinematics to reach the following performances:

a

workspace of 500x500x200mm

a

workspace of 500x500x200mm

with

a guaranteed acceleration of 40m.s-2 all over the workspace whatever

the direction is

with

a guaranteed acceleration of 40m.s-2 all over the workspace whatever

the direction is

a footprint

width limited to 1700mm

a footprint

width limited to 1700mm

This machine was devoted to be a drilling and taping,g unit for the automotive industry.

Acknowledgments: François Pierrot

related links: PKM news, Renault Automation - COMAU, CNRS info, linear motors and high velocity, Exam on UraneSX

|

|

|

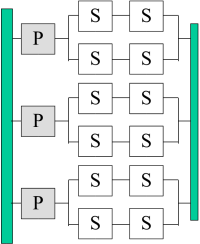

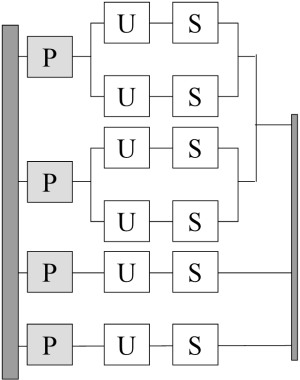

| UraneSX joint and loop graph |

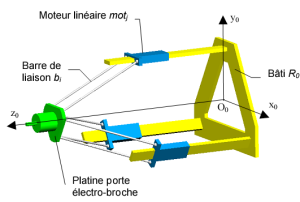

kinematics scheme |

|

|

|

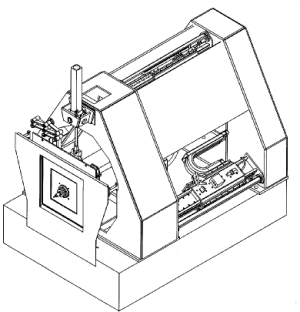

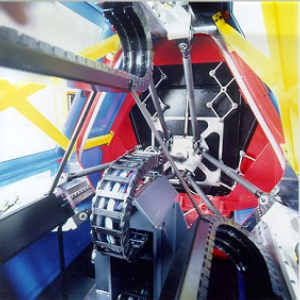

| machine arrangement | Internal view |

|

|

|

| machine view | Commercial video |

During Robotool project, I proposed a new concept of articulated traveling plate (1999). The first robot using this concept was the H4 robot. It is made of four kinematic chains made of spatial parallelograms (these chains are identical to the Delta robot ones). These chains join the fixed base to the articulated traveling plate that has the shape of letter H, made of three bars and two revolute joints. This robot is a pure Schoenflies motion generator. The initial rotation range of the end effector was +/-45 degrees. This was not enough to tackle industrial pick and place tasks. An amplification system, made of gears was added to reach a +/-180 degrees rotation range.

Acknowledgments: François Pierrot, Frédéric Marquet, Bruno Florençon, Tessaru Sibukawa, Pr. Massaru Uchyama, Choi HB Young, Reg Dunlop, Jacques Marie Hervé

|

|

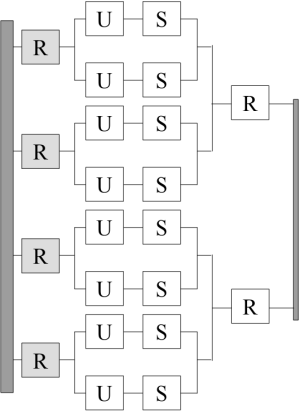

| Linear Asymetrical H4 joint and loop graph | Linear Asymetrical H4 CAD model |

|

|

| Rotative Symetrical H4 joint and loop graph | Rotative Symetrical H4 kinematics scheme |

I worked also with Frédéric Marquet on the actuation redundancy. The result is the ARCHI robot prototype. This planar kinematics provides 3 degrees of freedom (two translations plus a rotation perpendicular to the plane defined by the two translations) has 4 actuators and four bars to drive it.

Acknowledgments: François Pierrot, Frédéric Marquet

The articulated traveling plate concept was further investigated and modeled by Sébastien Krut during his PhD. He proposes the I4L and I4R concepts. The strong improvement regarding H4 architecture was obtained thanks to the replacement of the two revolute joints of the articulated traveling plate with prismatic joints. This has very positive effects regrading symmetry of the design and singularity removal. The models of robots of I4 family were also simpler to compute. On the other hand, we noticed that prismatic joints are not compatible with high speeds and accelerations.

Acknowledgments: François Pierrot, Sébastien Krut , Torgny Brogradh

As prismatic joints are not well suited to high speeds and accelerations, we decided to go back to articulated traveling plates. The H4 traveling plate was transformed from the H shape to a planar parallelogram. This new design removes singularities and allows the a symmetrical design. Thanks to the symmetrical arrangement of the Par4, it was possible to obtain a prototype of a robot devoted to pick and place that can compete with the ABB flexpicker. The main features of Par4 prototype are a workspace of about 1000mm diameter and a height of 100mm. The real workspace, is of course bigger. The acceleration reached in this workspace is about 150m.s-2. The prototypes built by industrial partners go faster every day...

Acknowledgments: François Pierrot, Vincent Nabat

We are still looking for new

concept of

articulated

traveling plates and we note that with H4 and Par4, a rotation motion

is created on the traveling plate and then amplified. The challenge, is

to remove this amplification device. On the other hand, there is the I4

family that generates a translation on the traveling plate and then

uses a devices (rack and pinion, cable an pulley) to turn it into a

rotation. the basic idea was to keep the advantages of the two concepts

and generate directly the +/-180degrees rotation range. The main

objective is to simplify traveling plate to make it light weight and

reliable. This was achieved thanks to an helical joint. The Heli4 robot

was born.

Acknowledgments:

François Pierrot, Vincent Nabat, Sébastien Krut,

Emilie Portales

Another interesting mechanism with an unlimited rotation capability was recently proposed: Dual4. This robot is a pure Schoenflies motion generator and is based on a modification of the Archi concept. Dual4 robot is not redundant, does not use any amplification or motion transformation device and can achieve an unlimited rotation. This concept is at an early development stage.

Acknowledgments: François Pierrot, Vincent Nabat, Sébastien Krut

Mic-Mac, an hybrid, near to singular configuration PKM

A first step in high resolution PKMs, was made during Stéphane Ronchi PhD. The goal of this research was to build parallel mechanisms is a near singular configuration to obtain a natural reduction (by a ration from 4 to 10) of the resolution of the actuators scale. This leads to the hybrid bi-planar Mic-Mac machine using flexture hinges to reduce backslash and friction.

Acknowledgments: François Pierrot, Stéphane Ronchi